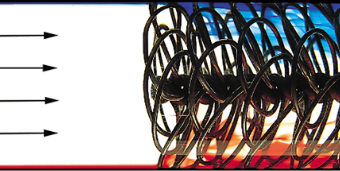

Single Phase Overview

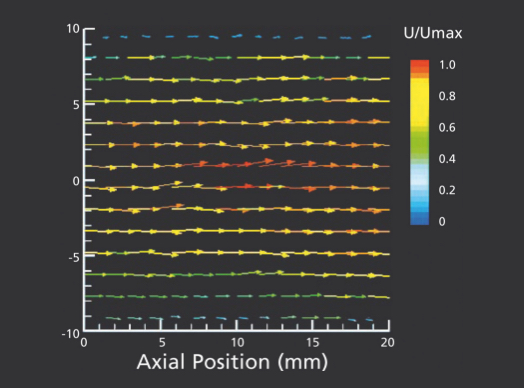

For very low mass flows or viscous flows, this can lead to laminar flow throughout the tube, in which heat transfer is dominated by conduction, limiting heat transfer rate. It is essential to also understand in turbulent flow conditions (higher mass flows) the heat transfer is still controlled by the boundary layer.

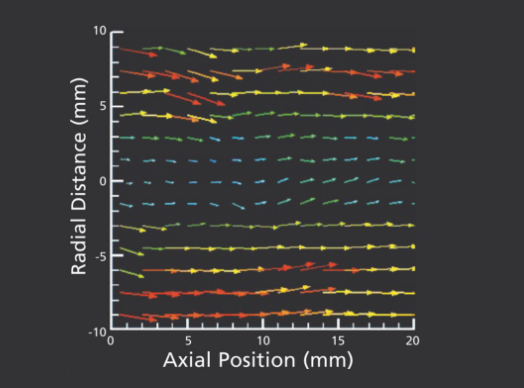

By installing hiTRAN® Thermal Systems in the tube, the laminar boundary layer will be disrupted, creating additional fluid shear and radial mixing of fluid into the bulk. In laminar flow, this augments the conductive heat transfer, thereby significantly increasing performance. Even in turbulent regimes the boundary layer disruption is still effective in increasing heat dissipation.

Features & Benefits

High efficiency in laminar and to transition flow regimes

Heat transfer increases are up to 16 times in laminar flow, up to 12 times in transitional flow and over 4 times in turbulent flow.

Predictable performance

Performance is proportional in transition flow, avoiding the controllability issues experienced in empty tube transition flow.

Increase in duty within pressure drop limits

With greater frictional resistance with hiTRAN, increased heat transfer in laminar flow enables designs to operate at higher heat transfer at lower or equivalent pressure loss.

Customer-designed product

Design variability allows full optimisation based on application parameters and requirements using our unique CALGAVIN®.SP algorithm.

New or Retrofit?

hiTRAN Thermal Systems can be applied for newly designed exchangers and also help debottleneck exchangers in the field, installed in situ.

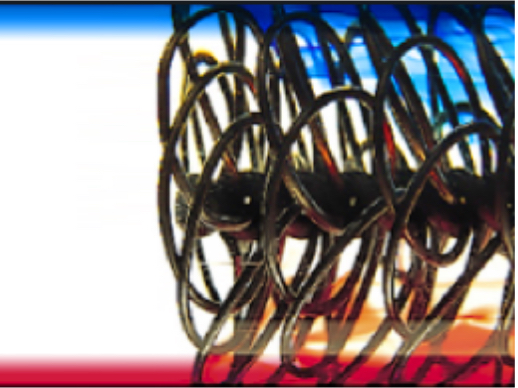

How it works