CELEBRATING 40 YEARS OF CALGAVIN

For 40 years CALGAVIN® has steadily built up an unrivalled expertise in thermodynamics, heat transfer and fluid flow phenomena, combined with global experience providing heat exchanger improvement solutions to hundreds of plants worldwide.To date CALGAVIN has supplied to 50+ countries, across 15+ industries, completing 17000+ orders of which 4800 successful retrofits have been delivered.

The company was founded on the development and sale of the heat exchanger tube-side technology hiTRAN® Thermal Systems. This success has led to the broadening of the company’s activities to provide a range of products and services all focused on heat transfer optimisation for process plants, minimizing energy use, capital investment & operating costs. Clients include Global energy companies, EPC contractors and equipment fabricators.

‘CALGAVIN has and will always rise to the challenge!’

The company founder Martin Gough collaborated with Prof. Ellis (Chemical Engineering department, University of Birmingham) to evaluate wire based turbulators and their function and benefit in heat transfer efficiency inside heat exchanger tubes.

Play Video

One of the early key retrofits in a Process plant in the North West of the UK. Vital positive learnings on the fouling mitigating effects of our developing product on Refinery residue applications were first understood. Managing Director Martin Gough and colleague shown during the retrofit.

Play Video

First overseas Exhibition – San Francisco showing the earlier Heatex branding, which was later changed to hiTRAN® Thermal Systems. This set the way forward in marketing globally.

Play Video

First overseas Asian exhibition in Japan. We utilised the translating assistance from a Professor of Chemical Engineering, assisting us in this expanding market.

Play Video

To support the development of our product and tomorrow’s engineers, CALGAVIN employs University placement students, teaching them fundamental heat transfer and business experience. To date CALGAVIN has in total worked with 20+ students. This has formed a major mindset of the company in investing in knowledge transfer.

Play Video

Moved to present facility, Minerva Mill Innovation Centre, Alcester. This move brought a larger space for manufacturing, Research & Development and Engineering staff, an Innovation hub within ‘Shakespeare country’.

Play Video

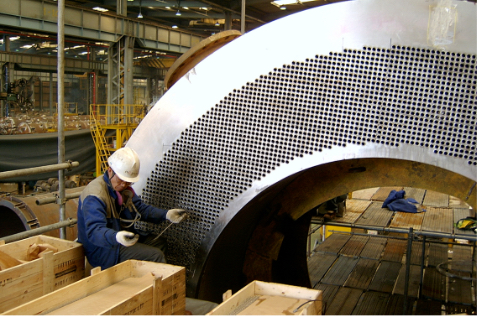

A pivotal installation of hiTRAN® Thermal Systems into a new column top condenser of 16,000 tubes, moved hiTRAN into a new era of application to large plant

Play Video

Launched hiTRAN®.SP design and selection program (integrated with HTRI Xchanger Suite® and Aspen Exchanger Design & Rating) CALGAVIN’s free to download software that models the performance of our hiTRAN® Thermal Systems used by many of our customers.

Play Video

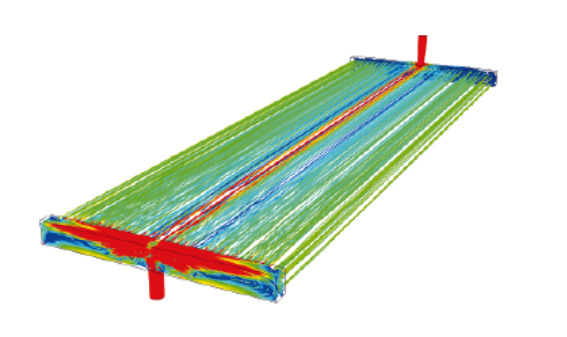

Adding to the services available from CALGAVIN, Computational Fluid Dynamics (CFD) Services are offered to the market. An important tool in troubleshooting heat exchanger underperformance.

Play Video

The new product development department is established, paving the way forward in understanding various phenomena encountered in thermal & process industries and the solutions required.

Play Video

The new Centre for Flow Processing, opening in 2020, will be the focal point for integration of commercial, research and university educational activities to position the UK at the forefront of this science led technology for future generations.

By offering state of the art Research & Development and production facilities under one roof, the aims of the CFP will be ‘world leading technology, skills and jobs for the UK’.

Play Video

New Headquarters for CALGAVIN

CALGAVIN® has invested in a new commercial development, in Alcester, UK, to which it will re-locate in 2023/4. This move is necessary in order to expand our business opportunities, develop new products of high commercial value, expanding human resource need, improved manufacturing space and layout requirement, and a larger more purpose designed area for research.

Having a ‘fit for purpose’ manufacturing facility for existing and new products will provide long term benefits right across the production and shipping process. A purpose built ‘home’ for CALGAVIN’s innovative future.

Play Video

Scroll down to see more

Scroll down to see more