Performance comparison Twisted Tapes – hiTRAN (Laminar Flow)

.jpg)

As a manufacturer of hiTRAN Thermal Systems and twisted tapes we are often asked about main differences between the technologies. To answer this, it is important to understand the different working principles. Here, at CALGAVIN’s research labs we have conducted extensive hydrodynamic and heat transfer studies which can be summarised as follows:

Hydrodynamics:

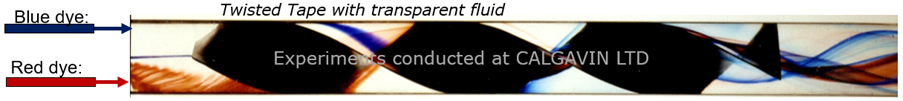

Figure 1:Dye injection in transparent flow to show flow behaviour in glass tube equipped with twisted tape

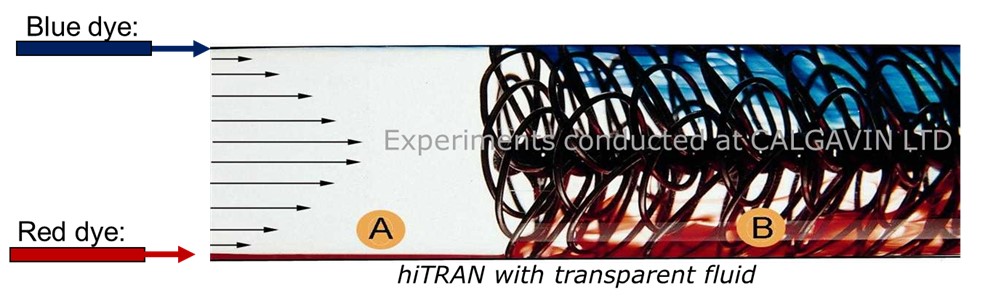

As seen in figure 1, twisted tapes redirect flow, promoting increased interaction with the tube wall. However, as shown in figure 2, the interaction of hiTRAN Thermal Systems shows a stark difference in the flow interaction at the tube wall (where heat transfer takes place):

Figure 2: Dye injection in transparent flow to show flow behaviour in glass tube equipped with hiTRAN

The hiTRAN near wall flow is much more disruptive with larger proportion of radial mixing compared to the twisted tape flow. This has also been observed with verified Computational Fluid Dynamics (CFD) simulations.

Figure 3: CFD velocity profile Re~850; Pr~170

Our CFD results have excellent agreement with hydrodynamic and thermal experimental data. In the video the observer travels with the flow inside the 22mm tube. The velocity vectors show, that the twisted tape increased rotational movement, but resulted in very little interaction of the bulk flow with the tube wall region.

Heat Transfer:

Extensive heat transfer studies of twisted tapes are available in the public domain, but in many cases these data sets contradict industrial performance due to the experimental conditions not matching real-world installations (e.g., swaged or brazed twisted tapes in tubes as opposed to loose-fit tapes). Furthermore, particularly in commercial software packages, these correlations are often unrealistically extrapolated beyond experimental range.

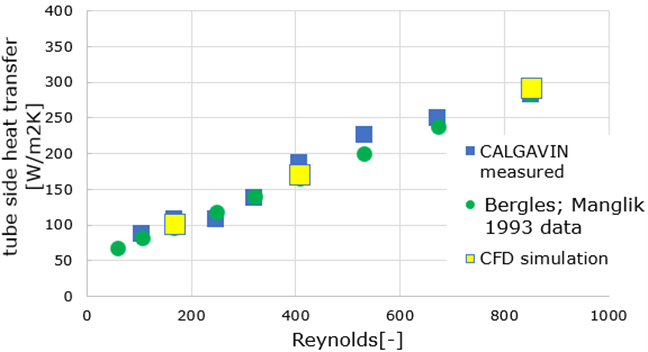

Figure 4: Twisted tape L/D~8, heat transfer as function of Reynolds

To overcome this shortcoming, CALGAVIN measured industrially relevant twisted tapes at our in-house heat transfer test facility. An example measurement is shown in figure 4. Experimental measurements were compared with open literature data and CFD simulations. The comprehensive overview paper from Bergles & Manglik [ 1993,Heat Transfer and Pressure Drop Correlations for Twisted-Tape Inserts in Isothermal Tubes, https://doi.org/10.1115/1.2911384], best represents our measurements and also CFD simulations.

We consequently compared twisted tape heat transfer in laminar flow with our warranted hiTRAN data. A comprehensive overview around the hydrodynamics and the related heat transfer when using hiTRAN can be accessed in our webinar hiTRAN Heat Transfer Enhancement in Single Phase Flow | Resource Portal

Figure 5 shows, as an example for laminar flow conditions at Reynolds 850, the heat transfer and pressure drop performance of hiTRAN versus twisted tape inserts.

.png)

Figure 5: performance comparison of hiTRAN and twisted tapes in laminar flow (Re~850; Pr~170; tube ID 22mm)

Firstly, the performance envelope in terms of heat transfer and pressure drop multiplier is narrow for the twisted tape range at industrially relevant L/D ratios. For the same pressure drop penalty, the heat transfer multiplier is around 50% higher when using hiTRAN technology. For lower Reynolds number, higher Prandtl Number / Viscosity conditions the benefit of hiTRAN versus twisted tapes is even greater.

The higher heat transfer multiplier potential of hiTRAN can be used in exchanger design by optimising the pass arrangement to stay within the allowable pressure drop. The ideal design tool for this is our software CALGAVIN.SP which integrates with HTRI and Aspen and can be downloaded here.

Takeaways twisted tapes versus hiTRAN under laminar flow conditions

Heat transfer performance:

Dependant on Reynolds number, however as rule of thumb hiTRAN yields around 30% to 80% higher heat transfer compared to twisted tape for similar pressure drop. Larger differences for lower Reynolds numbers.

Pressure drop:

hiTRAN yield higher pressure drop, however in laminar flow this can be compensated by low velocity designs [reduced number of passes]

Process warranty:

Twisted tape correlations differ widely in literature. Often extrapolated from original measured geometry. (extrapolation with respect to L/D, Tube diameter, Reynolds range Prandtl range). Due to tube tolerance gap between tape and tube wall not determined. Gap influence on performance poorly understood. Manufacturer nor thermal design software provides thermal nor hydraulic warranty.

CALGAVIN gives thermal and hydraulic warranty on hiTRAN when designed with CALGAVIN.SP.

Performance warranty backed up by highly precise in-house measurements. More than 1000 hiTRAN geometries tested and optimized over relevant Reynolds (0.1 < Re < 200000), Prandtl (0.7 < Pr < 12000), tube geometry (6mm < di < 42mm) range.

Further reading and webinars

Webinars:

hiTRAN Heat Transfer Enhancement in Single Phase Flow | Resource Portal

Twisted Tape: A 19th Century Product in a 21st Century World | Resource Portal

A Comparison of Twisted Tapes and hiTRAN Thermal Systems | Resource Portal

Further reading: